Fine Tuning Our Stocking Program

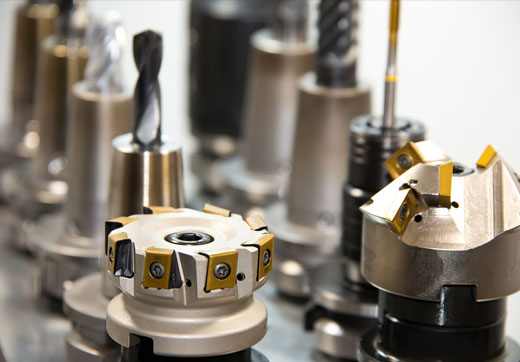

Semco values all our customers, and we strive to ensure that first-time clients become long-term clients. We offer excellent benefits to companies and individual that stick with us for their graphite engineering and machining needs, and we’re always working to offer more. Hence, our efforts at fine tuning our stocking program. If your need for graphite materials or components is relatively predictable, our personalized stocking program can deliver products consistently to you at a fixed price. This is good for your budgeting, and good for your workflow. And if you like how our stocking program helps your business, then it’s...

Read more