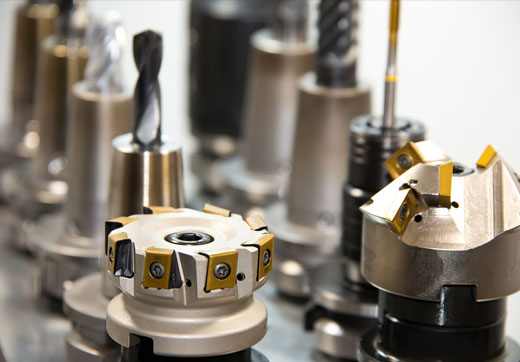

Measuring On-Time Delivery and Scrap Rates

Good businesses will find ways to synergize efficiency and incentives, creating feedback between the two that benefits customers, employees, and the bottom line. At Semco, we have developed a measuring and incentives system to improve our delivery times and to reduce our scrap rates. Semco knows graphite applications, which means we know how important is it that your graphite products be precisely machined according to your specifications the first time. We also know how important speedy delivery is to our customers—when you need a graphite component to keep up production, you need it fast. We started our measuring program to...

Read more