Understanding the Properties of Graphite for Aerospace Applications

The aerospace industry demands materials that can perform reliably in the most extreme conditions imaginable. All rocket science jokes aside, there is little room for error in aerospace engineering and only the most formidable materials make their way into aerospace applications. From the intense heat of rocket engine combustion to the electromagnetic interference challenges in modern avionics, aerospace engineers need materials with exceptional properties. Graphite, with its unique combination of characteristics, has become indispensable in aerospace applications ranging from rocket nozzle components to lightweight carbon fiber structures.

Lightweight Yet Strong

Weight matters (like, really matters) in aerospace applications, where every pound affects fuel consumption, payload capacity, and performance. Think of the scene from The Martian where the NASA scientists tell Matt Damon’s character to remove more and more weighty pieces from his rocket so that it can escape Mars’s atmosphere. Graphite's exceptional strength-to-weight ratio makes it ideal for structural components in satellites, aircraft, and space vehicles where weight savings directly translate to mission success. Unfortunately, for Earth’s atmosphere, a canvas tarp just won’t do for a rocket nozzle.

But perhaps a carbon fiber tarp would? We’ll have to consult with NASA’s engineers about that. Carbon fiber reinforced composites, which rely on graphite's carbon structure, do provide strength comparable to steel at a fraction of the weight. This allows engineers to design aircraft components, satellite structures, and spacecraft frames that meet demanding strength requirements without the weight penalties of traditional materials.

Thermal Stability in Extreme Conditions

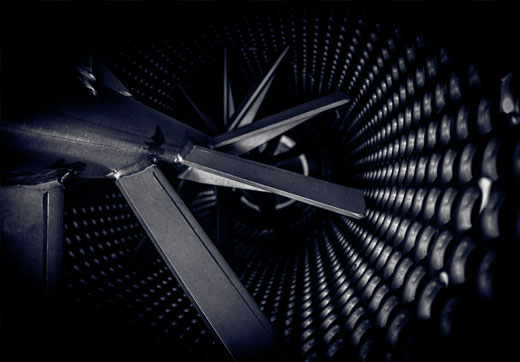

Perhaps no aerospace application demands more from materials than rocket engine systems. The extreme temperatures generated during combustion—often exceeding 5,000°F—would destroy most materials instantly. Graphite's exceptional resistance to high temperatures means that it shows up in rocket nozzle construction, where it must withstand intense heat while maintaining structural integrity (a graphite specialty).

As they say, what goes up must come down, and graphite is also useful in this re-entry process of rockets as well. In fact, you will find graphite serving critical roles in thermal protection systems (TPS) and re-entry vehicle heat shields. These applications require materials that can absorb and dissipate enormous amounts of heat without degrading or losing their protective properties. Graphite's thermal stability ensures that spacecraft and re-entry vehicles can survive the intense heating experienced during atmospheric entry.

Self-Lubrication in the Vacuum of Space

Space presents unique challenges for mechanical systems. Conventional lubricants either evaporate in the vacuum of space or freeze in the extreme cold. Graphite's natural self-lubricating properties make it the preferred material for bearings, seals, and moving parts in spacecraft and satellites where traditional lubrication methods simply cannot work.

This self-lubricating characteristic comes from graphite's layered crystal structure, which allows the material layers to slide over each other with minimal friction. Satellite solar panel deployment mechanisms, spacecraft gimbal systems, and various moving components in space vehicles rely on this property for reliable operation throughout their missions. You could say that graphite is the WD-40 of spacecraft.

Electrical Conductivity for EMI Protection

Modern aircraft and spacecraft contain sophisticated electronic systems that must function reliably despite exposure to electromagnetic interference (EMI) from solar flares and cosmic radiation. Graphite's electrical conductivity makes it valuable for EMI shielding applications, protecting sensitive avionics and communication systems from interference that could compromise mission safety.

Lightning strike protection represents another application of graphite's electrical properties. If you’ve ever flown through a thunderstorm, you may have experienced the anxiety that comes from the thought, “how will this plane not explode if we’re struck by lightning?” Commercial and military aircraft require materials that can safely conduct lightning strikes away from fuel systems and other components that are necessary to keep the plane aloft between destinations. Graphite-based materials provide this protection while maintaining the lightweight characteristics essential for aerospace applications.

Corrosion and Chemical Resistance

Aerospace environments expose materials to extreme chemical conditions, from the corrosive exhaust gases in jet engines to the harsh chemical environments encountered in the upper atmosphere and in space. For instance, atomic oxygen (O1, not the stable O2 that our lungs prefer) is plentiful in low Earth orbit. Graphite's chemical stability in these extreme chemical environments supports its use in jet engines, fuel cells, and high-temperature sensors where other materials would quickly degrade.

This chemical stability proves particularly valuable in propulsion systems, where materials must withstand exposure to aggressive propellants and combustion byproducts while maintaining their structural and functional properties.

Precision Machinability for Custom Components

The aerospace industry frequently requires custom components manufactured to extremely tight tolerances, something we know a great deal about at Semco. Graphite's excellent machinability allows for the production of precisely engineered parts like electrodes for aerospace manufacturing processes, as well as specialized components for avionics and propulsion systems.

This machinability of graphite enables graphite machine shops like Semco to create complex geometries and intricate details that would be difficult or impossible to achieve with other high-temperature materials. The ability to machine graphite to precise specifications makes it invaluable for prototyping and producing specialized aerospace components.

Real-World Applications

These properties combine to make graphite essential across numerous aerospace applications. Rocket nozzles rely on thermal stability and machinability. Satellite components benefit from lightweight strength and vacuum lubrication properties. Aircraft systems utilize electromagnetic interference shielding and lightning protection capabilities.

At Semco Carbon, we've seen firsthand how graphite's unique properties make it indispensable for aerospace applications. Our experience machining precision graphite components has given us deep appreciation for how this material's characteristics translate into real-world performance advantages. As we explored in our previous blog on aerospace and graphite, the relationship between graphite properties and aerospace requirements makes this a match made in heaven (or in low earth orbit at least).