The Importance of Maintenance in Graphite Machining

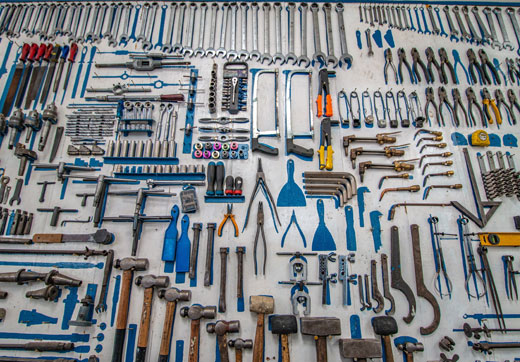

At Semco, carbon graphite is king. That material that makes up all our graphite components is the star of our graphite fabrication story. A less discussed, but critically important, subject in our story of graphite fabrication is graphite machining maintenance. The high quality of the graphite components we manufacture depends on the proper functioning of our machines. Semco is dedicated to keeping these machines running efficiently and producing quality graphite parts from carbon graphite. Hence, we have implemented scheduled maintenance for all our equipment done on site by our knowledgeable employees. Occasionally, when our state-of-the-art, complex machines have breakdowns that...

Read more